Fire-insulated Roller Shutter

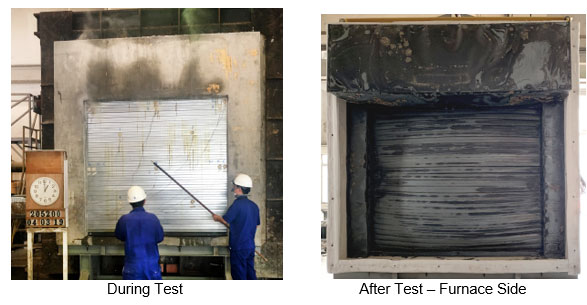

In a fire situation, a deployed fire shutter can turn red-hot when subjected to the full force of the flames and intense heat can radiate from the shutter curtain. This radiated heat is capable of igniting combustible materials that may be stored on the other side, hence allowing the fire to spread. The solution to this is the use of Fire Insulated Shutters.

Most fire codes permit the use of fire shutters as compartment walls but they need to be insulated.

In premises where highly combustible materials are stored, the fire shutters should also be insulated. The objective is to effectively prevent the spread of fire through radiated heat.

The IFS-4G is our latest 4th generation design. It offers the following features :-

- Steel curtain design, simple and space-saving

- Steel slats on both exposed curtain surfaces provides fire insulation against fire attacks from any direction

- Robust and impact resistant - can function as a security shutter

- Suitable as an external shutter, weather resistant design with PVC bottom weather seal

- Durable – built for daily usage

- Rigid curtain – can accommodate air pressure differentials generated by mechanical vents

- Self-supporting design – steel guide posts transfer most of the shutter weight to the floor

- Can be configured to fully close within 30 sec or 60 sec where required

Tested to BS EN 1634-1 2014 + A1 2018, EN 1634-1 2014, SS 489:2015, MS 1073:1993 and TCVN 9383:2012

IFS-4G 60 offers 120 minutes of integrity with 60 minutes of fire insulation

IFS-4G 120 offers 120 minutes of integrity with 120 minutes of fire insulation

IFS-4G 240 offers 240 minutes of integrity with 240 minutes of fire insulation

Patent Information :

Europe - No. EP22212780.5

Malaysia - No. PI 2022007044

Singapore – No. 10202250456K

Taiwan - No. 111147665

Vietnam - No. 1-2022-08115

The IFS-2G has the following features:-

- Symmetrical design, provides fire insulation for fire attacks from any direction. This is a necessary criteria if used as a compartment wall

- Steel slats on both exposed curtain surfaces – for durability and impact resistance

- Suitable for use as an external shutter, with PVC bottom weather seal

- Can double-up as a security shutter for daily usage

- Rigid curtain – can accommodate air pressure differentials from mechanical vents

- Do not need guide encasements (unlike most insulated fire shutters)

- Can meet any regulator-prescribed closing speed (e.g. 10 to 30 secs for Singapore)

- Fail safe model available where required.

- DfMA friendly – can be supplied fully-assembled for easy incorporation into any PPVC module

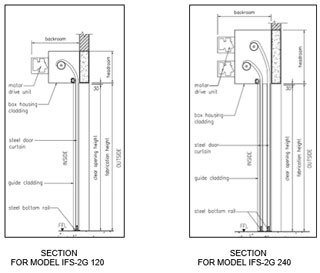

We have 3 models, all with maximum Width of 12.0m & max Height of 7.0m :

IFS-2G 60 offers 60 minutes of fire insulation with fire integrity of up to 240 minutes;

IFS-2G 120 offers 120 minutes of fire insulation with fire integrity of up to 240 minutes;

IFS-2G 240 offers 240 minutes of fire insulation with fire integrity of up to 240 minutes.

Tested to BS EN 1634-1

Patent Information :

Australia - No. 2019213465

China - No. ZL 201980008518.0

Hong Kong - No. HK40027543B

Japan - No. 6906110 B2

Macau - No. J/005787

Malaysia - No. PI 2020003132

Singapore - No. 11202005130P

Taiwan - No. I723370

UK - No. GB 2581465

USA - No. 11,047,170 B2

Technical Data

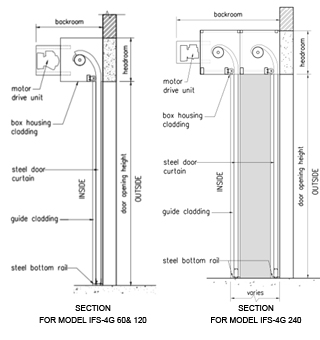

Drum Assembly

The barrel assembly consists of an extremely rigid steel tube sheathed over a pair of drive shaft assemblies fitted to heavy duty bearing sets and supported at both ends by steel head plates. The drive shaft is a solid polished steel round bar incorporating key ways to accept the drive sprocket. Corresponding to the size of the shutter, the head plates are either 6mm or 8mm thick with shafts of either 38mm or 50mm diameter.

The entire drum assembly is enclosed by a housing consisting of 1.0mm thk galvanized steel sheet cladding secured over an insulation layer of fire boards.

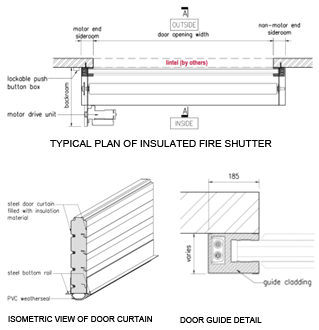

The IFS-4G incorporates a self-supporting structure in the form of a ‘goal-post’ made up of steel ‘C’ channels. The entire shutter box and barrel assembly rests on this structure, thereby transferring the bulk of the weight to the floor. The head plate is then anchored to the wall to secure the shutter vertically.

Door Curtain

For IFS-4G, the shutter curtain is formed by a single layer of steel interlocking cavity slats spanning the entire width of the door opening.

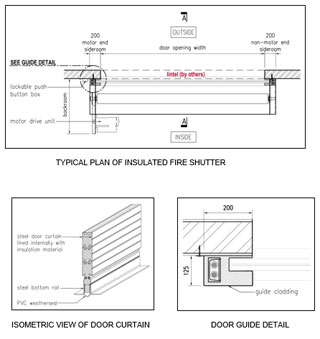

For IFS-2G, the door curtain consists of two walls of steel interlocking slats that are attached to a single barrel such that they roll and unroll as one. The slats of each wall are faced away from the other, with the concave faces forming the exposed surfaces of the walls.

Model IFS-2G 240 has two such curtains rolled unto two separate barrels, with an air-gap in between.

Door Curtain Material

Slats

For IFS-4G, each slat consists of a continuous length of an inner and an outer steel profile. They are connected back-to-back by modular stud brackets without the use of any exposed fasteners. This unique design secures the two profiles together while keeping them thermally separated. The voids between the two profiles are filled with insulation material to form a dense core.

For IFS-2G, the slats are specially-designed interlocking profiles that are roll-formed from galvanised steel material of various thicknesses. The internal surfaces of the slats are lined with an insulation blanket comprising of mineral wool and fire-resistant fabric. The blanket is securely attached to the slats in an innovative way, without puncturing the insulation materials with fasteners.

End Clips

Custom-shaped steel end-clips are secured to the ends of the slat to prevent lateral movements.

Bottom Rail

The bottom rail is formed by 2 lengths of 50mm x 50mm x 2.0mm thick steel angles secured back-to-back through a medium of fire boards. A PVC weather seal covers over the fire boards and seals against the floor when the shutter is fully closed.

Door Guides

The door guides are a pair of modules formed by fire boards built around the steel ‘C’ channel vertical guide posts. The back of the guide module is finished with galvanized steel cladding.

The steel ‘C’ channel guide posts also act as vertical structural supports by helping to transfer the shutter weight to the floor.

Door Operation

Motor Drive

The drive unit consists of a suitably-sized linear drive motor operator mounted parallel to and behind the door roll. It has an integrated gearbox and a chain operated sheave wheel for manual operation in case of power outage. The control box is lockable, housing a set of push buttons for Up’, ‘Down’ and ‘Stop’ operations. The door operation shall automatically stop at the desired upper and lower limits via adjustable limit switches.

Inevitably, the curtains of all insulated fire shutter designs are quite heavy, exceeding the capacities of conventional shutter operators. As such, the IFS-2G employs a custom-built motor operator to manage the weight of its two walls of insulated steel curtain.

For safety reasons, the ‘DOWN’ button shall require the operator to push and hold when closing the shutter. This is to ensure the closing operation is being supervised. Upon sighting an obstruction, the operator will automatically release the push button by reflex. This action will instantly stop the downward travel of the shutter and prevent accidents.

Power supply requirement: 3 Phase 415V x 20amp isolator to be provided for each motor.

Fire Activation

The motor operator has a versatile control adaptability that can enable it to respond to a wide range of activation modes, including Fire Alarm signal, smoke or heat detectors, fusible links etc.

In certain situations, a fail-safe operating configuration may be required. This is available as an option.