Blast Shutters

Conventional roller shutters can become hazardous debris in a blast situation. This often occurs in oil and gas facilities which experience accidental release of flammable materials resulting in a vapor cloud explosion. To mitigate this hazard, Gliderol had developed a blast-resistant roller shutter in consultation with ABS Consulting of USA.

The two-phase development program includes the use of finite element analysis (FEA) to design the door system and then validate the model with a full-scale shock-tube test of the working model.

Our design approach is to allow the shutter curtain to plastically deform under blast pressure and progressively arresting the moving components of the curtain. These components are made up of elements that are connected to prevent them from becoming debris.

We achieved this with a curtain supported by horizontal steel connector rods that are attached to vertical wire ropes at both sides. The wire ropes are restrained at the top and either unrestrained (for PL1) or tethered (for PL2) at the bottom

The development program culminated with the shock tube testing of 2 units of full-scale working models, each measuring W 3700mm x H 4950mm. The test results* were in excellent agreement with the FEA analysis using the measured test loads for both PL1 and PL2 configurations. In all the tests, minimal permanent damage was observed and no debris was produced.

This validation indicates that our FEA model can be reliably used to assess the likely performance of our blast shutter for alternative dimensions or blast loads.

Our Blast Shutter is capable of two performance levels:

1) BLAST MITIGATING (PL1)

PL1 (without bottom restraints) has been tested and shown to be capable of achieving limited damage in response to a blast load with peak pressure 75 kPA and peak impulse 1050 kPa-ms; and

High-speed camera images of PL1 test

2) BLAST RESISTANT (PL2)

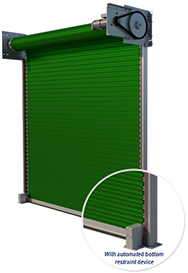

PL2 is fitted with a pair of automated bottom restraint device that will work with the motor operator to ensure that the restraints will always engage whenever the shutter is in the closed position. PL2 has been tested and shown to be capable of achieving limited damage and be fully retained in response to a blast load with a peak pressure 40 kPA and peak impulse 500 kPa-ms.

High-speed camera images of PL2 test

Suggested Performance Objectives:

PL1 will absorb blast load through large displacement, minimize blast load reactions on the structure and prevent component failure and debris generation. It will also permit egress following the blast loading.

PL2 will absorb blast load through limited displacement, minimize door response and intrusion into occupied space, and prevent component failure and debris generation.

*Full test report can be viewed from our website http://www.gliderol.com.sg/test-reports-certification.html

PATENT INFORMATION:

WIPO Publication No. WO 2020-246941A1

Australia – No. 2019341063

Canada – No. 3,174,041

China – No. 2019800055611

Europe – No. 19 856 411.4

Hong Kong – No. 62021029240.0

Japan – No. 7108693

Korea – No. 10-2335678

Macao – No. J/006061

Malaysia – No. PI 2020002272

New Zealand – No. 762462

Singapore – No. 11202002050W

Taiwan – No. I715120

USA – No. US 11,187,030 B2

Vietnam – No. 1-2020-06364